- Home

- >

- News

- >

- News activities

- >

- Interpretation of the friction welding process in the drill pipe industry

Interpretation of the friction welding process in the drill pipe industry

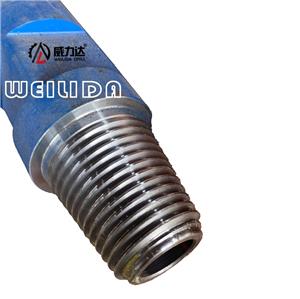

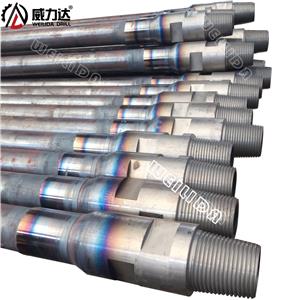

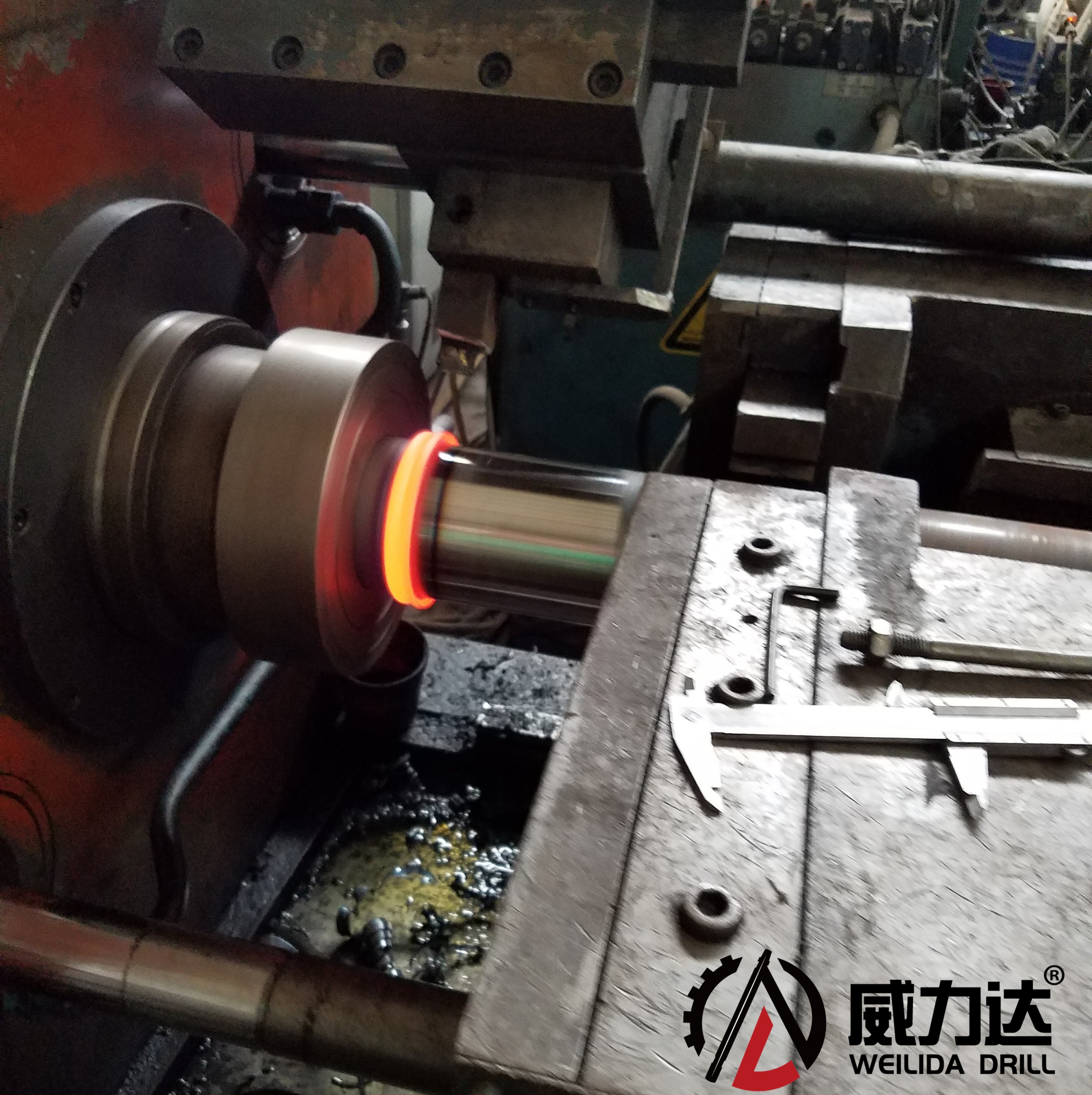

Friction welding (FRW) is a solid-state welding process that generates heat through mechanical friction between workpieces in relative motion to one another, with the addition of a lateral force called "upset" to plastically displace and fuse the materials. Because no melting occurs, friction welding is not a fusion welding process in the traditional sense, but more of a forge welding technique. Friction welding is used with metals and thermoplastics in a wide variety of aviation and automotive applications.

![]() Friction welding drill pipe.mp4

Friction welding drill pipe.mp4

Advantages:

The production practice proves that friction welding, which is one of the thermo-compression weldings, has the outstanding advantages in addition to the advantages of general thermo-compression welding.

1. The quality of the welded joint is high and stable. Basically, the pass rate of 100% can be achieved, and the joint strength generally exceeds the base metal.

2. Has a wide range of solderability. It can be used not only to weld the same metal materials, but also to the welding of dissimilar metals with large differences in performance.

3. The dimensional accuracy and geometric accuracy of the weldment are high.

4. Reduced manufacturing costs. In friction welding, the welding allowance of the weldment is small, the assembly requirements of the weld are not high, the welding power is small, and the electric energy is saved.

5. Good working conditions. There are no sparks, arcs, no harmful gases, no vibration, no noise, etc.

6. Friction welding is easy to achieve full automation.

We have 80tons, 200tons, 320tons of friction welding machine, The pipe body is connected with joint by continuous and inertia friction welding technology, through computer monitoring to ensure the superiority of drill pipe.