- Home >

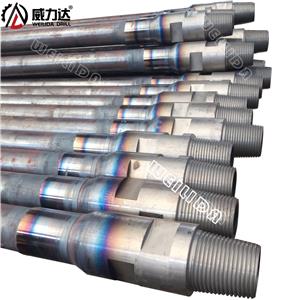

- Shijiazhuang Weilida Prospecting Machinery Co., ltd, a powerful drill pipe manufacturer

Shijiazhuang Weilida Prospecting Machinery Co., ltd, a powerful drill pipe manufacturer

Shijiazhuang Weilida Prospecting Machinery Co., Ltd. We have whole set of automation and high precision equipment to ensure high quality and stability of products.

1. 1300T joint horizontal forging and upsetting machine enhances the impact toughness of the joint, guarantees the compactness of the joint, and with the hard wear-resisting and good uniform, thus to guarantee the comprehensive mechanical property of the tool joint.

2. Automatic multi-purpose integration thermal treatment furnace.

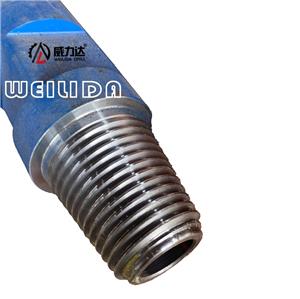

3. Thread processing equipment. we adopt precision CNC lathe to process all pipes to ensure the surface smooth finish of the thread and the stand-off of precision.

4. Large hydraulic upset and thickening equipment with super long and smooth transition belt, fast forming speed, and good stability. we use 400tons, 500tons, 80tons of pipe end upset thickening equipment to thicken the upsetting, to make all products reach the standard of API 5DP.

5. Friction welding machine. We have 3units of 80 tons, 200 tons, 200 tons of friction welding machine. The pipe body is connected with joint by continuous and inertia friction welding technology, through computer monitoring to ensure the superiority of drill pipe.

From customers’ order to every link of production, and to inspection and delivery of the finishing products, we record all the data.

Adhering company’s consistent philosophy, we buy all material from large steel factory in domestic.

According to the ISO9000 quality certification standards, and to make sure the quality of goods in every link through the strictly test program.

all products are strictly controlled from material purchasing to manufacture.

We equiped many checkout equipment like universal tensile testing machine, impact testing machine, metallographic microscope, various of sclerometer, spectral composition analyzer, Ultrasonic online testing equipment, magnetic particle detection device, monomial parameter instrument of screw thread etc. All of these equipments can reach WEILIDA inspection requirements and the promise of product quality.

We establishes complete and traceable documents according to API 5DP requirements and trace each piece of product according to it. To make sure the traceability of products we make labels, lettering and paint marking and so on. All complementary requirements and PSL requirements can be traced for each drill pipe. Pipe body and joint can be traced to corresponding furnace number. Welded joint can be traced to batch number of welded joint, mechanical property and other testing results.

Operators will inspect each work piece with thread gauge and recording data after finish processing screw thread.

Quality control engineers make test for each parameter by monomial parameter instrument of screw thread.