- Home

- >

- News

- >

- News activities

- >

- How to maintain the drill pipe?

How to maintain the drill pipe?

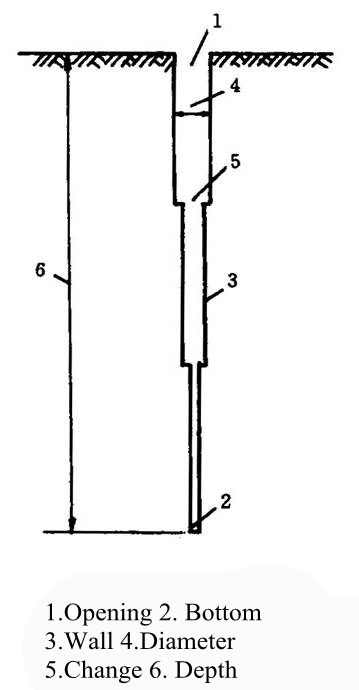

The drill pipe plays an extremely important role in the drilling process. If the drill pipe is not properly used and maintained, it is easy to accidentally break the drill pipe, etc., because the probe connected to the drill pipe is worth a lot of money, ranging from a few thousand dollars to tens of thousands of yuan. Once the drill pipe is broken, this will be a major economic loss. So how do we use and maintain the drill pipe?

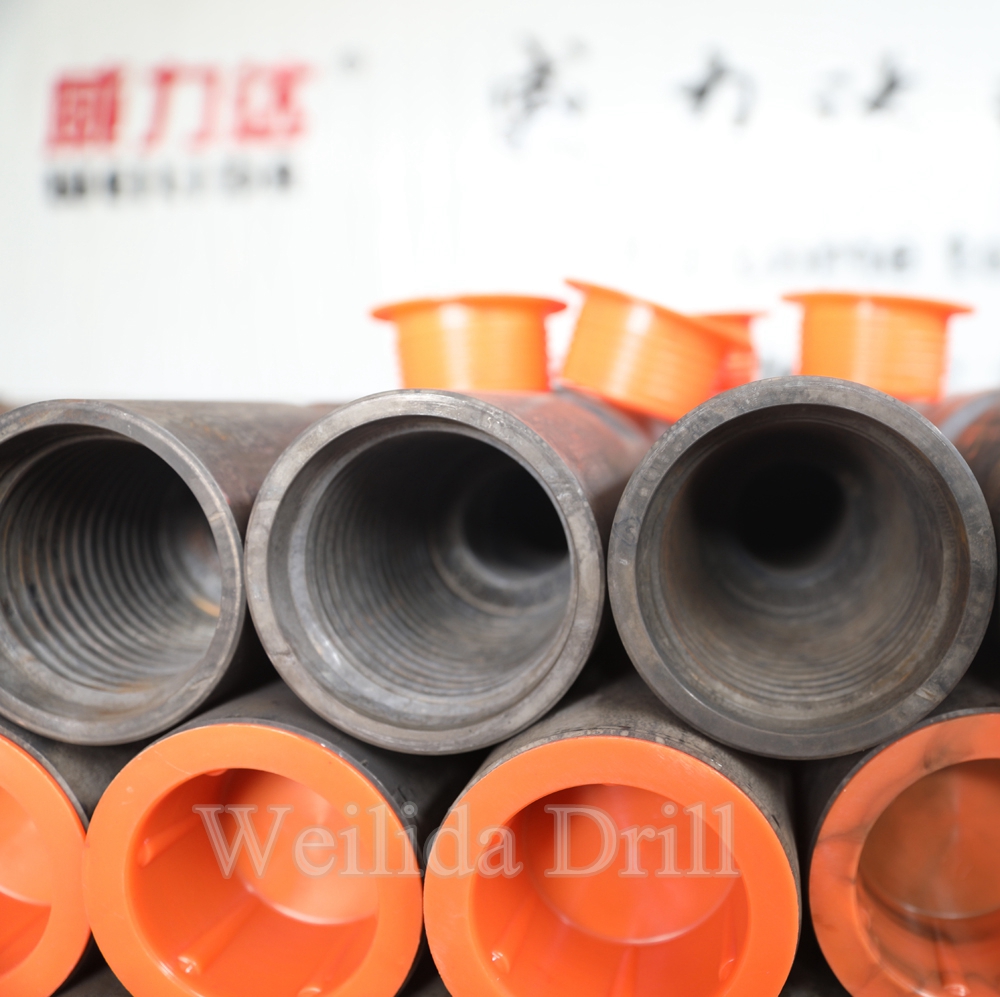

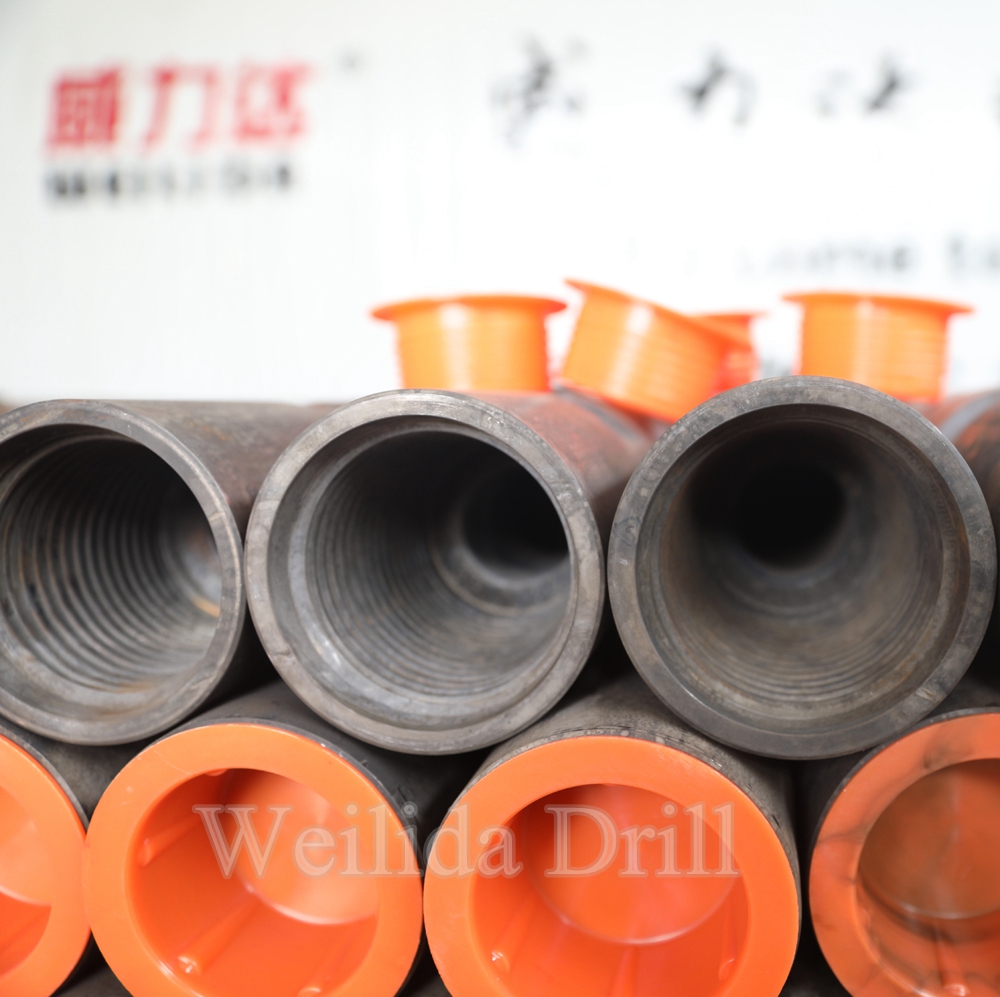

When the new drill pipe is used for the first time, wipe the protective grease on the drill pipe thread, clean the inner wall of the drill pipe with air or water, and then apply the thread oil to the internal and external threads of the drill pipe to prevent damage to the thread or the fastener.

2. When drilling, try to ensure that the drill hole is vertical and avoid the premature wear of the drill pipe caused by the deflection or bending of the drill hole.

3. The starting rod should be connected between the impactor and the first drill rod, otherwise the first drill rod will be damaged prematurely.

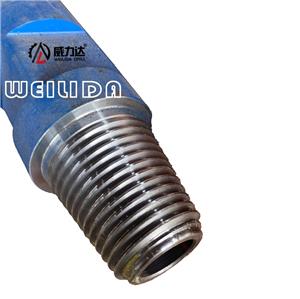

4. When connecting the drill pipe, remember to apply the thread oil to the drill pipe thread and tighten the drill pipe; if it is not tightened, the thread connection is loose, causing the threads to grind the top of the tooth to become sharp, resulting in thread damage or sticking; no tightening The female buckle step is not pressed, resulting in air leakage, which causes fatigue fracture of the root of the male joint thread.

5. When connecting the drill pipe, the male buckle can not collide with the shoulder and thread of the female buckle, and ensure that the male and female joints are centered, and the upper female buckle cannot be forcibly buckled. Ensure the coaxiality of the drill head and the connecting drill pipe.

6. Check the wear of all parts of the drill pipe. If abnormal wear occurs, find out the cause in time:

a. Is there a sharp hard object (or hard rock edge) in the hole to scratch the drill pipe. Please use caution when the drill rod body is scratched <0.5mm deep and in a circumferential (spiral) state. If the scratch depth is ≥0.5mm, it is forbidden to use and avoid the loss of the drill pipe.

b. Whether the drill hole is skewed, bent, or collapsed, causing the drill pipe to wear or deform.

c. Construction in abnormal layers such as pebble layer, fault layer, reinforced concrete layer, etc., resulting in damage to the drill pipe.

7. The following conditions are normal wear and tear, pay attention to the timely replacement of the drill pipe:

a. The outer surface of the drill pipe joint or the rod is evenly and smoothly worn, and the outer diameter is less than the standard size of 2 mm after being worn;

b. The male and female joint threads are even and smooth, and the crown is sharp.

8. It is not allowed to mix drill pipes of different manufacturers to prevent premature wear of the gluing or thread. Because the technical parameters, processing methods, tools and processing equipment used by the manufacturers are different in precision, the thread tolerances and tight distances of the machining must be different.

9. Drill pipes with large differences in old and new or large differences in wear should not be mixed to avoid construction hazards.

10. When the drill pipe is difficult to shackle, use a small hammer to gently vibrate the threaded part of the joint. It is strictly forbidden to use a sledgehammer to violently tap the joint, causing damage to the thread.

11. It is found that the drill pipe thread has a local small range (about 1-2 buckles, buckle length 10mm) damage, and should be repaired with a file in time.

12. The drill pipe should be stored in the open air for a long time. Before the storage, the drill pipe should be wiped clean and the anti-rust grease should be applied to the threaded part and the protective cap should be put on. Avoid impact damage to the male buckle when handling the drill pipe.