- Home

- >

- News

- >

- Trade News

- >

- Buy Geology Sample Rig Quotes, Supply Stratum Explore Machine Brands, China Assise Explore Facility OEM

Buy Geology Sample Rig Quotes, Supply Stratum Explore Machine Brands, China Assise Explore Facility OEM

Buy Geology Sample Rig Quotes, Supply Stratum Explore Machine Brands, China Assise Explore Facility OEM

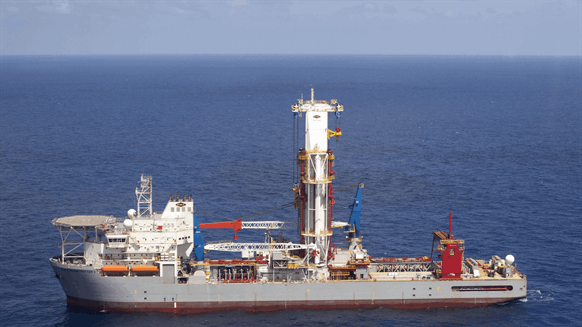

Digitization at Work: GE and Noble Launch Digital Rig

GE and Noble Corporation plc have teamed up to introduce Digital RigSM, the world’s first digital drilling vessel as the companies aim to digitize marine operations and make them more efficient.

Innovation has been at the forefront of operations both during the downturn and in its recovery.

The Digital Rig solution, powered by GE’s Predix platform, is targeted to achieve 20 percent operational expenditure reduction across the targeted equipment as well as detect potential failures up to months before they would occur.

Digital RigSM has been deployed on the Noble Globetrotter I drilling vessel and been successfully connected to all targeted control systems. Data is collected through individual sensors and control systems, harmonized and centralized on the vessel before transmitting in near real time to GE’s Industrial Performance & Reliability Center for predictive analytics.

“The potential of digitalization will go beyond a single vessel, opening the door to transforming our entire fleet. The data backbone paves the way towards autonomous drilling, and digital technology is facilitating a new era of drilling and asset performance improvements that are unprecedented,” Bernie Wolford, senior vice president – operations for Noble, stated in a release.

GE’s Marine Solutions general manager Andy McKeran added that by partnering with Noble, they “are in a unique position to unlock synergies together—from drilling operations to equipment expertise and software analytics skills—to drive holistic transformation of the offshore industry.”

The Digital Rig solution combines data models from a digital replica of physical assets, known as a digital twin, along with advanced analytics to detect off-standard behavior, providing an early warning to operators to mitigate a problem before it strikes. Personnel both on the vessel or onshore can gain a holistic view of an entire vessel’s health state and the real-time performance of each piece of equipment onboard.

“As the digital twin continues to acquire information, we will be able to learn from analytics results, which will shed new light on maintenance effectiveness as well as help us explore other possibilities to further improve drilling efficiency in marine settings,” said McKeran.

The companies will soon start running analytics on equipment’s real-time data on the edge to localize performance improvements and asset intelligence. The remaining three targeted vessels are on schedule to be digitalized for operational optimization early this year.